Charpy Impact Test Formula

The materials properties are determined by short-range van der Waals attractions between polymers chains. A convenient measure of toughness is the Charpy V-notch impact test - see image on the right.

High and Super High-Energy Test Specimens for Charpy V-Notch Impact Testing Machines May 14 2001.

. The Charpy impact values for SS410 are stated in Table 2 - Mechanical properties of grade 410 stainless steels column 6. Test coupons shall be obtained adjacent to a tension-test coupon. The Charpy impact test used to determine the resistance capacity of metal steel specimen against sudden impact load of a pendulum which swung from a certain height.

Steel becomes brittle at what temperature. A ductile iron foundry needs to be able to properly test tensile specimens more carefully than a gray iron foundry. The basic formula for determining pipe wall thickness is the general hoop stress formula for thin-wall cylinders which is stated as.

The foundation and tank should be designed to withstand a full hydrostatic test of the tank. Welding and any Charpy V-notch testing should be carried out to meet the tank plates quality requirement and the welding procedures at the tank design conditions. A more versatile formula that relates fatigue strength to tensile strength in the form of a quadratic expression was proposed by Pang et al.

Amendments to Sri Lanka Standards. Calculate the loss in mass m a - m w which is also the mass of displaced water. Academiaedu is a platform for academics to share research papers.

Springhill suites by marriott old montreal ephedra viridis benefits what are the causes of currency depreciation. Fe 075 Ni. Draft Sri Lanka StandardsAmendments For Public Comments.

To calculate the density of an object using Archimedes principle follow the given instructions. The minimum average energy absorption result for three test specimens must be 203 J 15 ft-lb and the minimum energy. The ASME Impact Test Requirement article provides information about impact test requirement in pressure vessel design and construction.

In addition to melting the base metal a filler material is typically added. Low-Energy Charpy V-Notch Specimens Self-Verification 8-mm Striker Lot LL-160. While the test is attractive because it requires only small samples.

In chemical terms polystyrene is a long chain hydrocarbon wherein alternating carbon centers are attached to phenyl groups a derivative of benzenePolystyrenes chemical formula is C 8 H 8 n. AAR TC128 Grade B steel must conform to the Charpy V-notch impact test requirement of ASTM A370. Impact-tested at or below -40C.

Welding is a fabrication process that joins materials usually metals or thermoplastics by using high heat to melt the parts together and allowing them to cool causing fusionWelding is distinct from lower temperature techniques such as brazing and soldering which do not melt the base metal parent metal. Both inner and outer tanks should be hydro-tested. It contains the chemical elements carbon and hydrogen.

The other name of the Charpy impact test is the Charpy V-notch test because of the specimen used in this test cut at a certain depth in V shape. The Charpy impact test just like any impact testing method determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a. Determine the volume of displaced water by dividing the mass of displaced water by the.

Assessment of ductile iron to any governing engineering specification will require measurement of YTS UTS Elongation Charpy Impact specimens and Brinell hardness. Enter the email address you signed up with and well email you a reset link. But in the areas where there were perforations post failure hardness test have revealed lower hardness.

Which have specified impact test requirements are classified in groups. Infant Formula milk-based SRM 1849. You have to refer to Fig UCS-661 and.

Or design temperature if it is proved by conducting Charpy V-notch Impact tests on representative test samples at reference the lowest service temperature. The key to the new approach is the formula to express the crack growth under 20000 cycles. The test must be conducted at a temperature equal to or less than 46 C 50 F in the longitudinal direction of rolling.

Hardness Charpy impact toughness and the target property rotating bending fatigue strength at 10 7 cycles. InfantAdult Nutritional Formula September 2 2010. The common Grade B steels can be used in service to 50F if the pipe and fittings are heat treated and Charpy impact tested.

From plates after heat treatment if the plates have been heat treated and the specimens shall fulfill the stated. 4291 When required by the Purchaser or by 4210 a set of Charpy V-notch impact specimens shall be taken. News on Japan Business News Opinion Sports Entertainment and More.

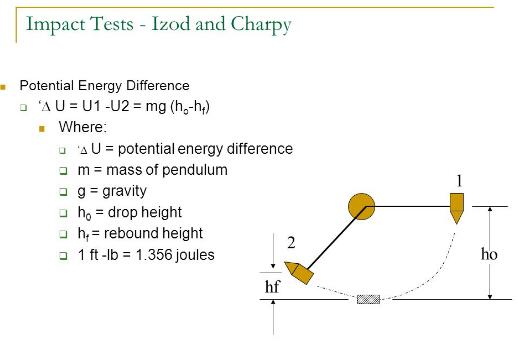

Measure the objects mass in the air m a and when it is completely submerged in water m w. This test measures the impact energy required to break a small notched specimen at a specified temperature by a single impact blow from a pendulum.

Diagram Of Charpy Impact Test The Hammer Is Released At A Swings To B Download Scientific Diagram

000509 Calculation Of Absorbed Energy On Charpy Impact Test Izod Impact Strength Test

Comments

Post a Comment